The Art of Casting: A Comprehensive Guide to Foundry Techniques

Introduction

Casting is a fascinating and complex process that turns a raw material into a functional object. In the non-ferrous foundry sector, this art form takes on even more exciting dimensions, with unique methods and materials. This guide will introduce you to some of the essential techniques used in non-ferrous foundry casting.

Non-Ferrous Metals

Non-ferrous metals like aluminum, copper, zinc, and lead are used in casting because of their unique properties. These metals are known for their resistance to rust and corrosion.

Techniques

Sand Casting: Sand casting is the most common method used in non-ferrous foundry. It involves creating a sand mold into which molten metal is poured.

Investment Casting: This method uses a wax pattern and ceramic shell to create highly detailed castings.

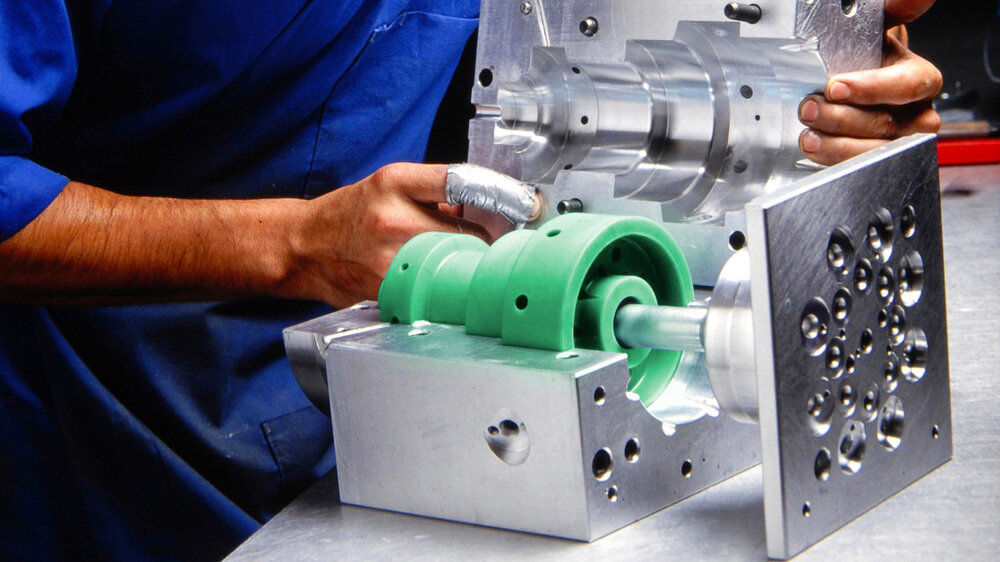

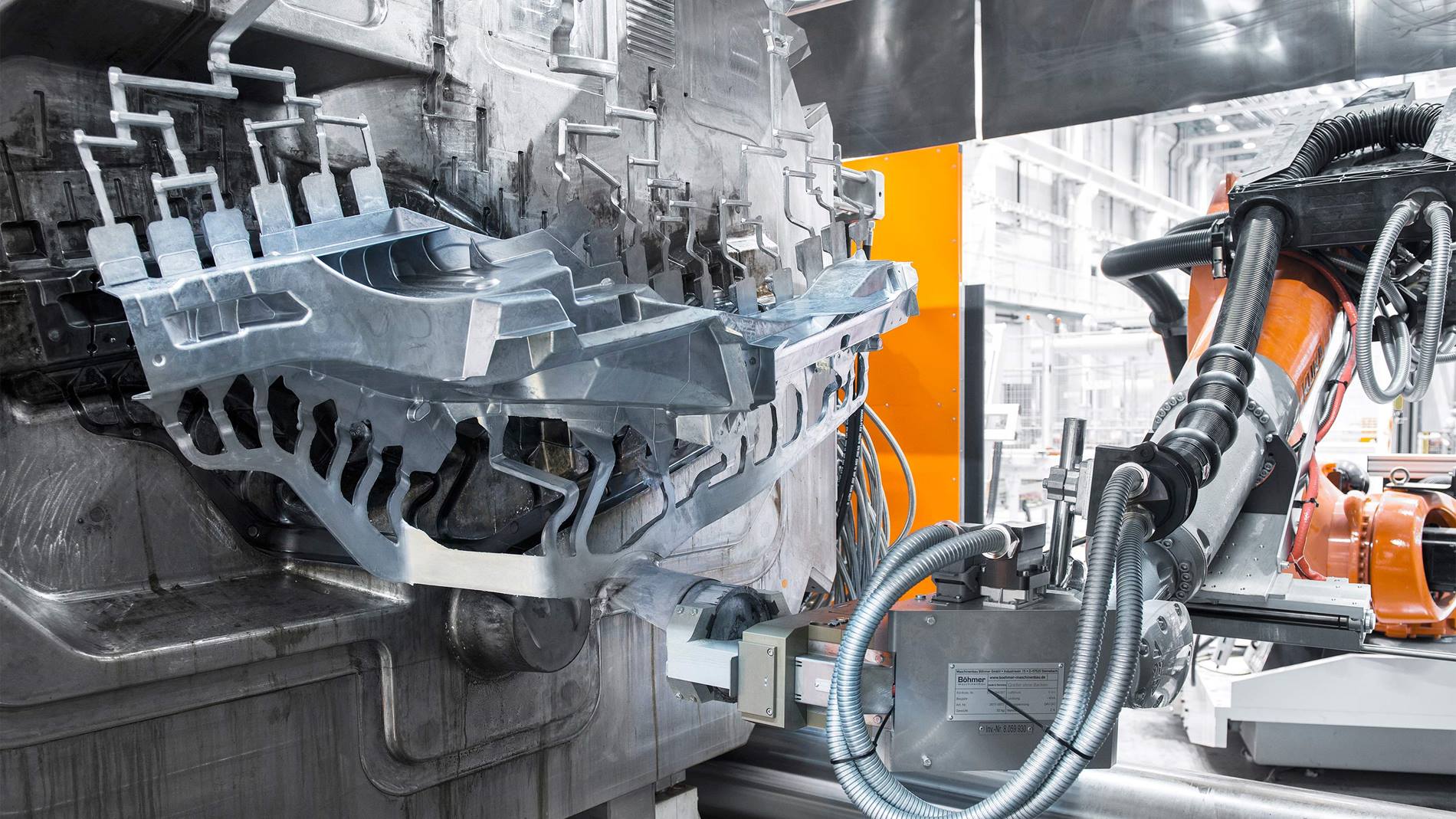

Die Casting: Die casting is a process where molten metal is forced into a mold cavity under high pressure.

Materials

The materials used in casting play a vital role in the process. Binders, coatings, and fluxes are essential to achieve the desired results.

Conclusion

The non-ferrous foundry process is a fascinating blend of science and art. Understanding these techniques is vital for those seeking to master the craft of casting.

#Foundry #NonFerrous #Casting #Metallurgy #SandCasting #InvestmentCasting #DieCasting

Comments