A Ship's Best Friend: The Importance of Quality Materials in Marine Engineering

Introduction

Marine engineering is a critical field that focuses on the engineering of boats, ships, oil rigs, and other marine structures. At the heart of any resilient and effective maritime structure is the careful selection and utilization of top-quality materials.

Quality Materials: The Backbone of Marine Engineering

1. Steel and Alloys

Steel, especially marine-grade steel, is commonly used in shipbuilding for its high tensile strength and corrosion resistance.

- Corrosion Resistance: Marine-grade steel contains elements like nickel and chromium, which provide protection against corrosion, a common problem in the marine environment.

- Strength: High-strength steel alloys provide the required structural integrity for withstanding the rigorous demands of the sea.

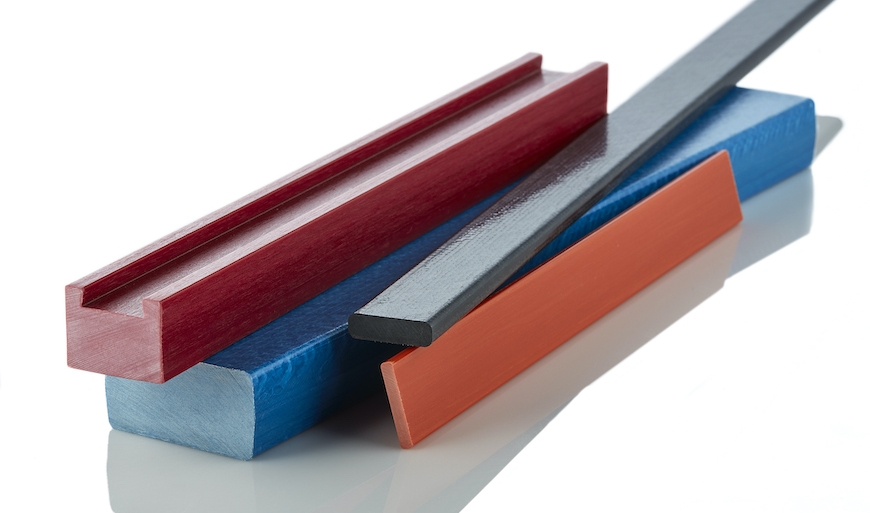

2. Composites

Modern ships often utilize composite materials, such as fiberglass, for lighter and more flexible structures.

- Weight Reduction: Composite materials are lighter than steel, improving fuel efficiency.

- Durability: Composites offer high resistance to water and environmental damage, enhancing the lifespan of maritime structures.

Conclusion

The selection of top-quality materials in marine engineering is not just about durability; it's about crafting maritime structures that can withstand the unique challenges of the marine environment. From steel and alloys to modern composites, the right materials are a ship's best friend, ensuring safety, efficiency, and longevity.

- #MarineEngineering, #Shipbuilding, #QualityMaterials, #MaritimeStructures, #Durability, #Efficiency

Comments